Optimize outcomes with implants 3D printed in PEEK

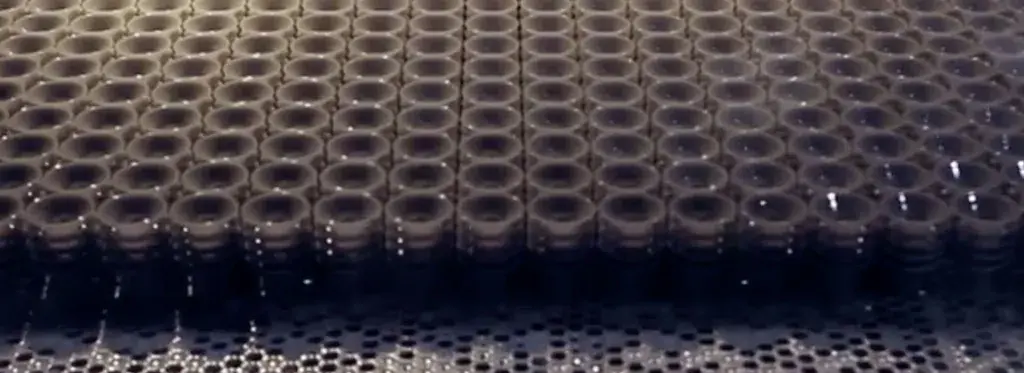

Improve the biocompatibility of medical devices with implantable PEEK. The lightweight material possesses high tensile strength with properties close to that of human bone, and it maintains its mechanical and chemical stability even at high temperatures. When PEEK polymers are 3D printed, you can produce implants and instruments in less time and with less waste than when traditional milling processes are used. You also gain design freedom to integrate lattice structures to further support osteointegration and to personalize implants to fit individual patient anatomies.

Printers Compatible with this Material:

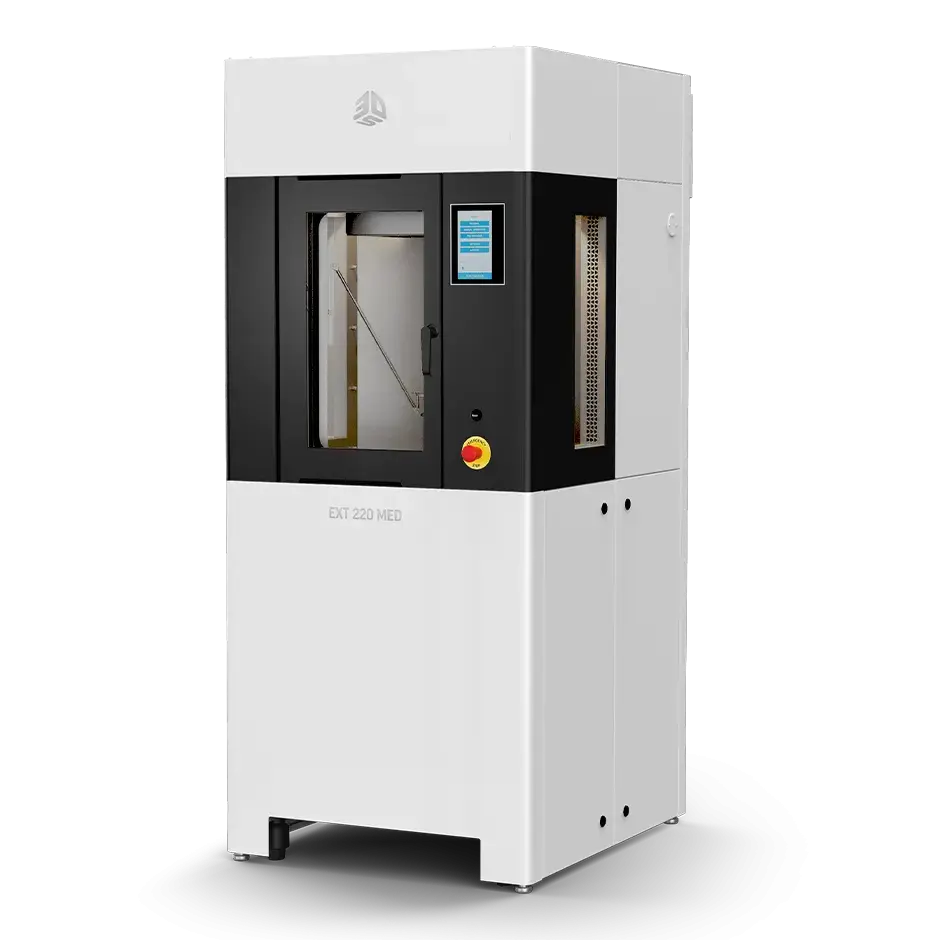

EXT 220 MED

L’unica piattaforma di estrusione dotata di una camera bianca integrata che è stata convalidata dai principali produttori di dispositivi medici e dagli ospedali di tutto il mondo.