Servizi per la lavorazione di lamiere

Una struttura in lamiera è una soluzione robusta e affidabile per svariate applicazioni.

Trovare il produttore giusto per creare le tue parti in lamiera è fondamentale, quindi cerca un partner che possa offrirti esperienza, tecnici esperti e linee produttive efficienti e ben gestite.

Quickparts è un fidato partner che può aiutarti a soddisfare ogni tua esigenza di produzione tradizionale e additiva. Il nostro team globale di tecnici specializzati e la nostra rete di impianti produttivi ti può fornire pezzi di qualità, quando e dove ne hai bisogno.

Come Funziona

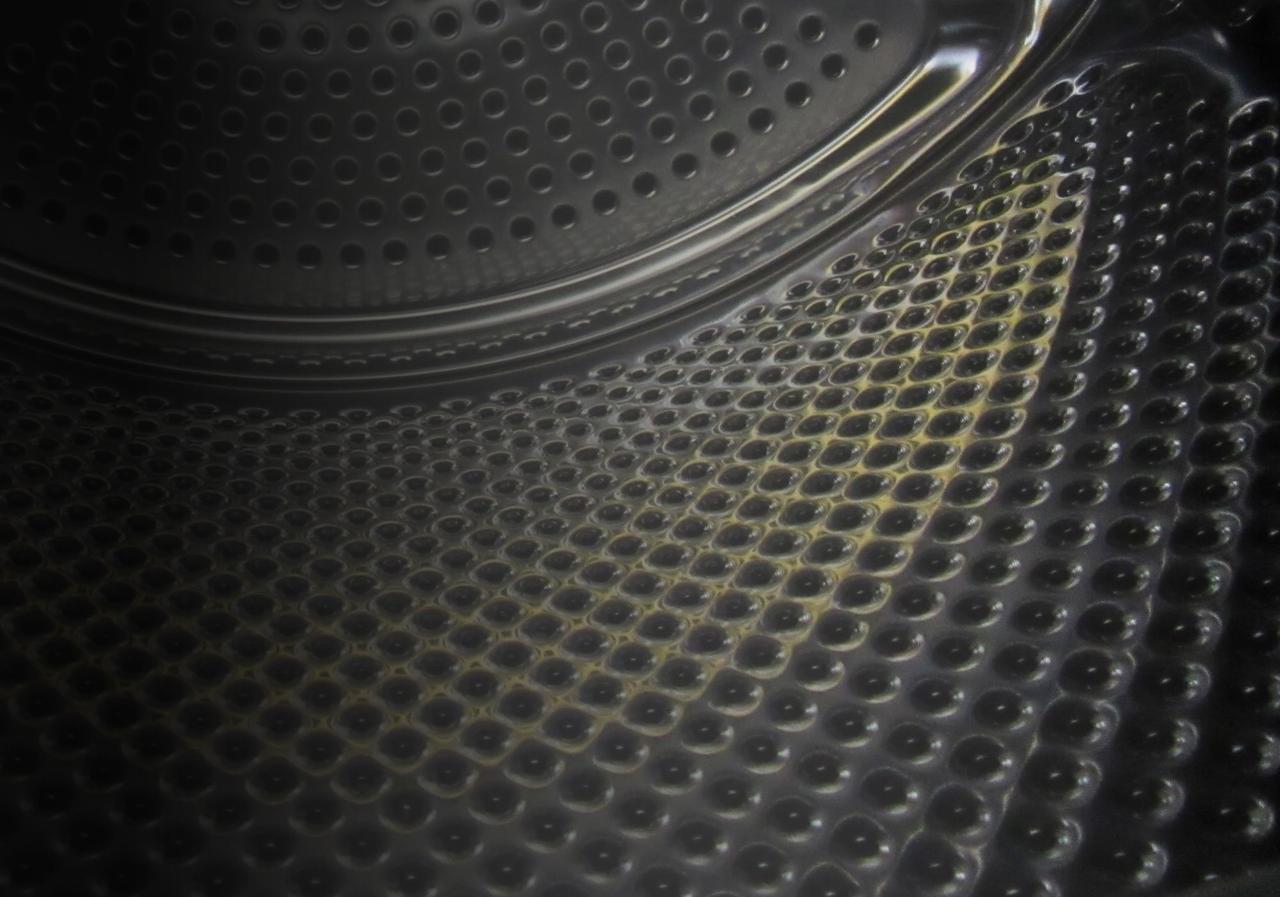

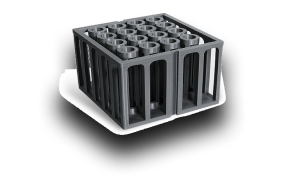

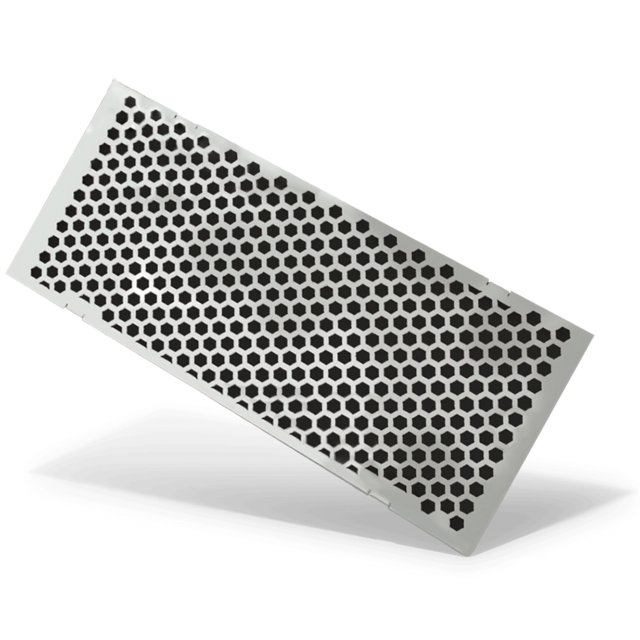

I servizi per la lavorazione della lamiera offrono varie possibilità, come la piegatura, la tranciatura, la punzonatura e lo stampaggio. Le parti vengono poi comunemente sottoposte a lavorazioni di foratura, maschiatura, controforatura e svasatura. Le soluzioni in lamiera possono adattarsi a molti progetti, dai più semplici prototipi in lamiera piegata fino ai cicli di produzione più complessi con assemblaggi di più parti lavorate.

Quickparts produce parti in lamiera tramite taglio laser, taglio ad acqua o processi di incisione chimica per formare i pezzi a partire dalla lamiera grezza. I pezzi ottenuti vengono poi piegati e formati utilizzando presse piegatrici o utensili rapidi personalizzati per ottenere la geometria finale. Ci occupiamo di tutti i servizi di lavorazione delle lamiere che vi servono tramite i nostri impianti all’avanguardia, tra cui formatura di metalli verticalmente integrata, taglio/foratura laser, lavorazione CNC, saldatura e celle di finitura, per supportare sia la realizzazione di prototipi che i cicli di produzione di involucri e carpenterie in lamiera di alta qualità.

Possiamo aiutarti a determinare qual è il processo produttivo più adatto al tuo progetto.

Di Quickparts

Quickparts è un’azienda pioneristica nel settore della stampa 3D.

Abbiamo inventato la prima piattaforma completa per la manifattura digitale, che offre servizi di produzione con tecnologie additive e tradizionali. Dalla prototipazione rapida alla realizzazione di modelli da esposizione, fino alla produzione in serie, Quickparts utilizza le tecnologie più avanzate e ha accumulato una grande esperienza per gestire qualsiasi progetto di produzione additiva.

Con strutture produttive dislocate in tutto il mondo, ciascuna dotata di personale esperto dedicato a soddisfare le tue specifiche esigenze nel modo più efficace e rapido possibile, puoi affidarti a Quickparts per ogni necessità di produzione.

Iniziare

Ti bastano pochi secondi per avviare un progetto con Quickparts.